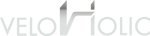

Absolute Black - HOLLOWCAGE® CARBON CERAMIC OVERSIZED DERAILLEUR PULLEY CAGE

HOLLOWcage® for Shimano 9100 / 8000. Our revolutionary mono-plate OSPW design is the quietest, best shifting, aerodynamic derailleur cage design created to date. It is a dawn of new era for rear derailleurs. HOLLOWcage ® OSPW has a carbon-polymer mono-plate construction with bespoke, oversized, full ceramic bearings and the most advanced silencing pulleys ever created.

Technical Data

|

Size (Mass +/-1g): |

71g |

|

Color |

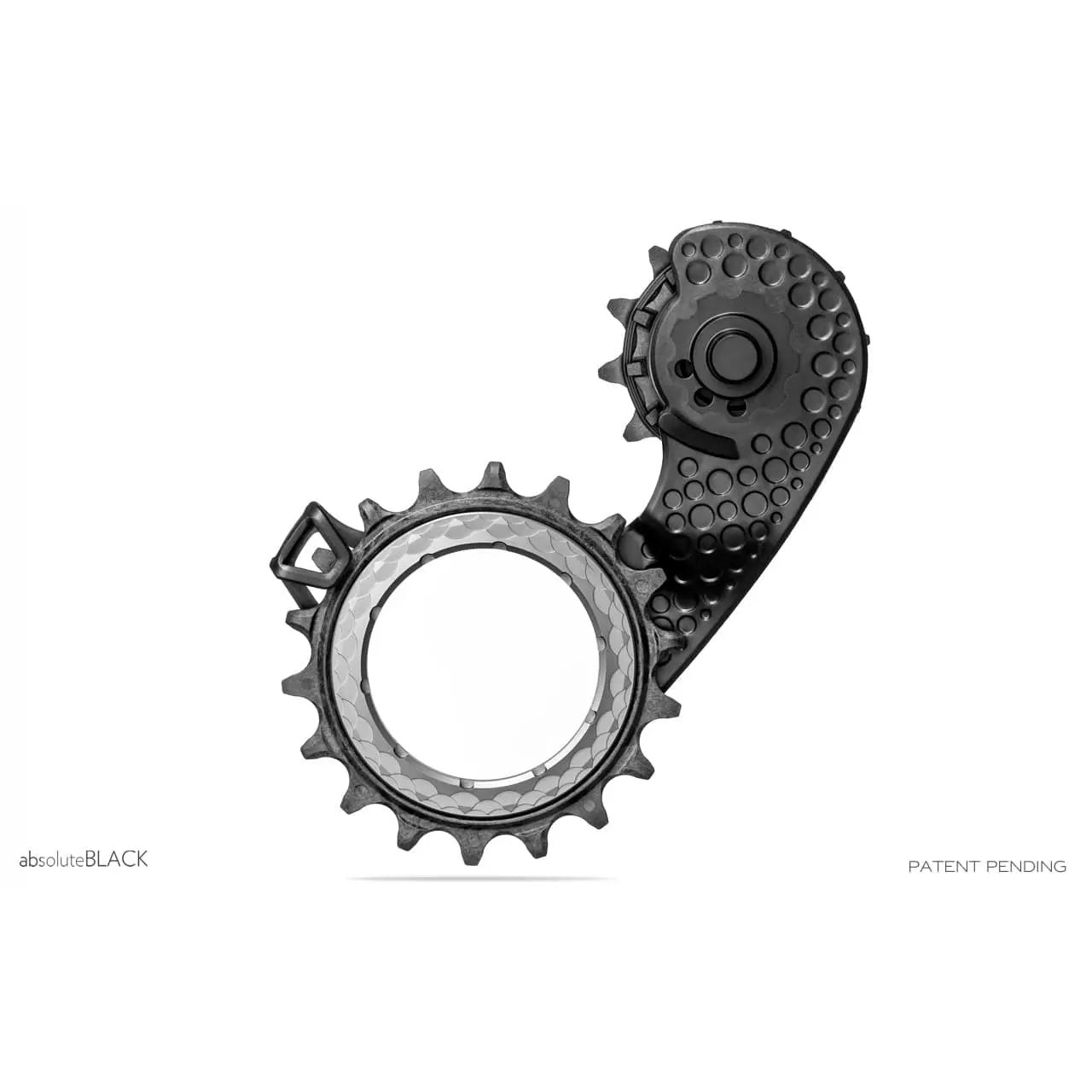

Lower lockring: PVD Rainbow, Black, Titanium, Red, Gold |

|

Compatibility: |

Shimano Dura Ace 9100 / 9150 / 9170 , Ultegra 8000 / 8050. Fits up to 32T cassette. NOT compatible with Ultegra long GS cage derailleurs.. |

|

Materials used: |

Carbon fiber-polymer matrix, 7075 Aluminium, rubber, ceramics |

|

In the box |

Complete cage, lockring tool, 2x spare xring rubbers |

WHY IS OUR OSPW HOLLOWCAGE® SO SPECIAL?

*It is super silent (over 12dB noise reduction vs stock).

*The shifting is as good as with the original Dura Ace cage.

*It’s more aero than the OEM cage and other oversized cages.

*It saves more watts than other cages

*One of the lightest oversized cages on the market.

*First mono plate construction of its kind.

THE NEW ERA OF SILENT PULLEYS. MEET THE SILENT XRING PULLEY ™

Does it bother you when you ride in a really quiet scenery but you can still hear your bike’s chain engaging the pulleys? This familiar clunking noise has been accompanying us on every ride for decades. It’s time for a change.

Common polymer pulleys are fairly loud, this has always been a norm. Aluminium pulleys are even worse as the material radiates the sound more than any polymer, making them louder. We are introducing a completely new generation of pulleys, which are able to reduce the sound level by 12-14dB when compared to stock Dura Ace pulleys. This corresponds to roughly 60% of the noise reduction. Practically speaking, the cage becomes very silent.

FLEXIBLE OSPW CAGE IS BETTER THAN A STIFF ONE.

Contrary to common knowledge, flexibility is good as it allows the cage (and therefore lower pulley) align better with the angle of the chain when using the higher gears of the cassette. This means less friction (and less Watts lost) as the pulley doesn’t have to fight against the chain itself. Shimano has partially solved this issue by bending the lower part of the cage slightly outwards, to align better with the chain when using top of the cassette range. We have taken a different approach and eliminated one part of the cage all together, creating mono plate cage that can dynamically adapt to the chain angle.

THE PROBLEM OF SHALLOW TEETH.

One of the main shifting issues, apart from pulley stiffness alone, stems directly from the low teeth profiles. Low teeth simply can’t move the chain effectively left or right when you change gear. They are the only points of contact with the chain, but for some bizarre reason, majority of oversized pulley systems come with very shallow teeth profiles. This is the major contributing factor to oversized pulley cages shifting badly. HOLLOWcage® uses very tall teeth of the upper pulley which gives the best possible shifting precision.

OVERSIZED OSPW CAGE IS ACTUALLY MORE AERO.

There is a general belief among some of the riders that oversized cages are less aerodynamic. Their larger surface area, when compared to OEM cages, must result in some power losses, which would offset the gains generated by the bigger pulleys. We have tested the market leading cage as well as original Dura-Ace cage in a bespoke wind tunnel, designed for smaller objects. HOLLOWcage® proved to be more aerodynamic than the OEM (DA cage) as well as the other leading brand.

STIFFER GUIDE PULLEY, NOT CAGE, MEANS BETTER SHIFTING.

Many companies try to convey that a stiffer cage is a better shifting cage. But the single most important factor that impacts the shifting is the upper pulley itself. Since the upper pulley is mounted directly to the rotating pivot axle, the flexibility of the cage plays very little role. It’s the upper pulley that moves the chain left and right enabling gear change, so making the upper pulley really stiff allows for greater shifting precision. Most oversized pulley cage systems use very small bearings, with a lot of lateral play at the teeth which in turn provide poor, sloppy shifting. HOLLOWcage®, unlike other pulley cage systems, use abnormally large, bespoke, full ceramic bearings that make the pulleys incredibly stiff. Lower bearing alone is actually big enough to fit 11T pulley inside of it.

HOW TO MOUNT HOLLOWCAGE

Please refer to the video instruction below. You should mount the cage with the lowest spring tension setting (First hole from left). If you use 11-32T cassette in combination with 52/36T chainrings or bigger you may need to set the cage with middle spring tension setting (middle hole) to account for the chain growth, but only if first position produces loose chain in small - small gear.

For service / maintenance instructions please refer to our FAQ page.

In the video below you will also find how to determine the correct chain length for your HOLLOWcage. Following this tutorial is crucial for the proper functioning of the drivetrain.

- Related products

- Recently viewed